Calgary Boiler Repair for Beginners

Wiki Article

The 7-Minute Rule for Calgary Boiler Repair

Table of ContentsThe Ultimate Guide To Calgary Boiler RepairCalgary Boiler Repair Can Be Fun For AnyoneThe 3-Minute Rule for Calgary Boiler RepairThe Only Guide to Calgary Boiler Repair

Annual evaluations of boilers should consist of a thorough exam of the water side surfaces for evidence of scaling as well as deterioration. An upward fad in flue gas temperatures over weeks or months normally shows that a down payment has developed up on either the fireplace or waterside of the boiler warmth exchange surface areas.

Having way too many overall liquified solids (TDS's) in the boiler water can create scale as well as minimize boiler efficiency. Consequently, it is needed to maintain the solids below particular limitations. As TDS concentration rises, it becomes most likely that the liquified solids will precipate out of the water as well as form range.

The smart Trick of Calgary Boiler Repair That Nobody is Talking About

Consistent as well as regular small quantity blowdowns is a much better practice than infrequent high quantity blowdowns, due to the fact that it saves energy, water, and also chemicals. Big vapor boilers with steady tons should have continual blowdown, where a percentage of water is drained constantly from the boiler while fresh makeup water is presented (Calgary Boiler repair).Pressure, water temperature, as well as flue gas temperature levels ought to be tape-recorded daily, as they can work as a standard reference for system procedure as well as troubleshooting issues. Much more comprehensive inspections and checks should be executed to document system efficiency, which can be very vital because a gradual change in system operating conditions gradually may not be readily noticeable without using such documentation.

The complying with Maintenance Checklists have actually been set up based on the suggested best techniques discovered in this file. Daily, Weekly, Monthly, Each year, Central heating boiler use/sequencing, Turn off/sequence unnecessary central heating boilers, X General visual evaluation, Full overall aesthetic evaluation to make sure all tools is operating and also security systems remain in location, X Follow maker's recommended treatments in lubing all components, Contrast temperature levels with tests done after yearly cleaning, X Check heavy steam stress, Is variant in vapor stress as anticipated under different tons? Wet heavy steam may be produced if the pressure drops also quick, X Inspect unstable water degree, Unsteady levels can be an indication of contaminates in feedwater, overloading of central heating boiler, tools breakdown, X Inspect burner, Examine for appropriate control as well as tidiness, X Check electric motor condition, Look for correct function temperatures, X Inspect air temperatures in boiler area, Temperatures should not exceed or go down below design restrictions, X Boiler blowdown, Validate the base, surface area and water column blow downs are taking place and also work, X Boiler logs, Keep day-to-day visit: Type and quantity of fuel utilized Flue gas temperature Makeup water quantity Heavy steam stress, temperature, and also amount created Try to find variations as a method of fault detection, X Examine oil filter assemblies, Inspect and clean/replace oil filters and also filters, X Inspect oil heating units, Inspect to make certain that oil goes to correct temperature level before burning, X Check boiler water treatment, Verify water therapy system is operating effectively, X Table resource: Federal Energy Monitoring Program, O&M Finest Practices Overview to Achieving Operational Performance Daily, Weekly, Regular Monthly, Annually, Check flue gas temperature levels and also make-up, Procedure flue gas composition as well anchor as temperature levels at selected shooting positions recommended O2% and CO2% Fuel O2% CO2% Gas 1.

All About Calgary Boiler Repair

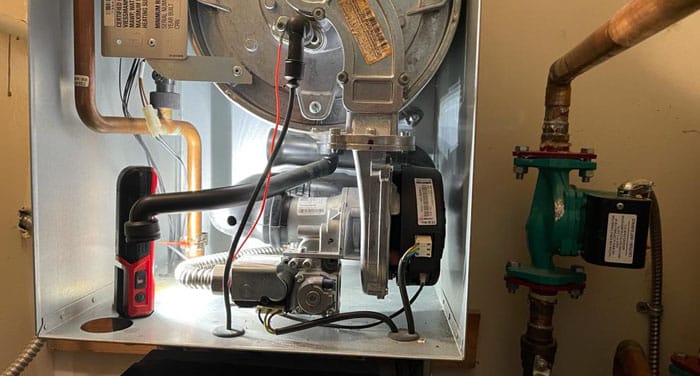

Hot water circulation systems are the most common property central heating boiler applications in Canada. Popular instances of heat distribution systems are cast iron radiators, copper fin baseboard radiators, in-floor radiant heat, and also air trainers. The fuel resource supplied to your residence can identify your options. One of the most usual boiler look at this web-site gas sources are gas, propane, and also electrical power.

We recommend you ask your HVAC expert or gas provider regarding any type of constraints. For many house owners, the deciding aspect for selecting a new boiler comes down to physical space. Depending upon the sort of central heating boiler, the system can be flooring standing or wall-mounted and also many come in both configurations.

These searchings for supply a quote of the warmth shed per hr for each and every room in your home. The wrong boiler size can negatively affect your device's performance and cost more to run. Your optimal central heating boiler will heat your whole residence without losing gas. A fantastic guideline is that the bigger your home, the larger the central heating boiler and also the higher the BTU outcome will certainly be.

The Best Strategy To Use For Calgary Boiler Repair

Relying on your warm distribution approach and also wanted performance, choosing a central heating boiler type boils down to your home's details needs. Each kind of central heating boiler has pros and disadvantages, relying on your space, budget plan, and also preferences regarding functions and tools effectiveness. The adhering to area notifies you about the sorts of boilers in Canada as well as how they run.

Mix boilers likewise described as combi-boilers can carry out both read the article area home heating as well as provide domestic warm water within one appliance. Combi-boilers consist of all running components within one system and are suitable if you want to conserve floor room or move far from storage-type hot water heater. Combination boilers are best for small to medium-sized homes as well as piled apartment townhomes.

Report this wiki page